Specialty Printing

Specialty Print Services, where creativity takes center stage! Discover the artistry of embossing, the precision of die cutting, the allure of foil stamping, and more as we unlock a world of possibilities to elevate your printed materials to new heights of sophistication and visual impact.

-

Foil Stamping

Foil StampingFoil stamping is a printing process that employs foil, usually metallic, high heat, and an engraved die to create unique images on paper and other materials.

-

Embossing

EmbossingEmbossing is the process of creating a raised or depressed surface on paper or other materials by pressing them against a die.

-

Die Cutting

Die CuttingDie cutting is a manufacturing process in which a die, or a metal cutting tool with a specific shape, is used to cut and shape materials, such as paper, cardboard, rubber, foam, or fabric.

-

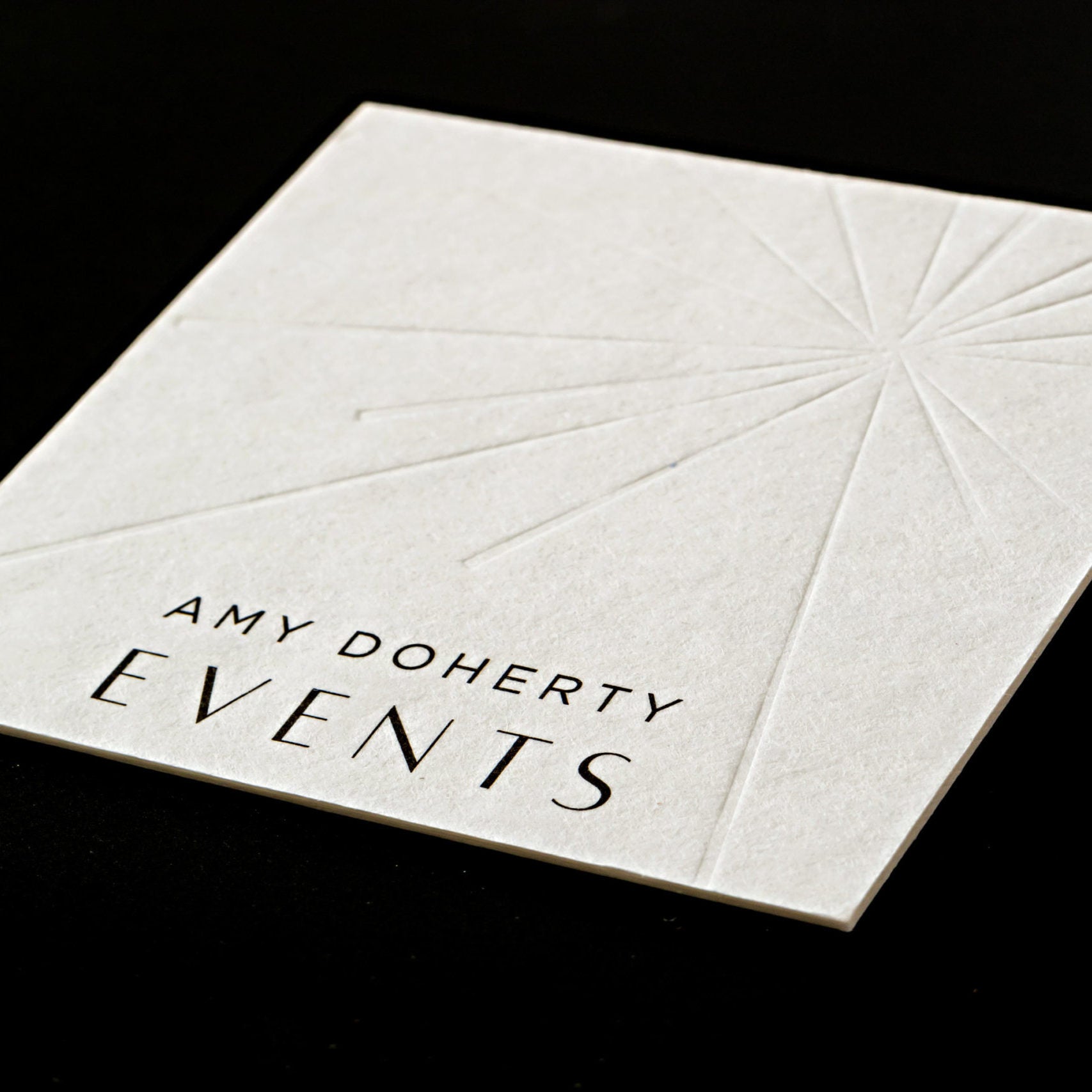

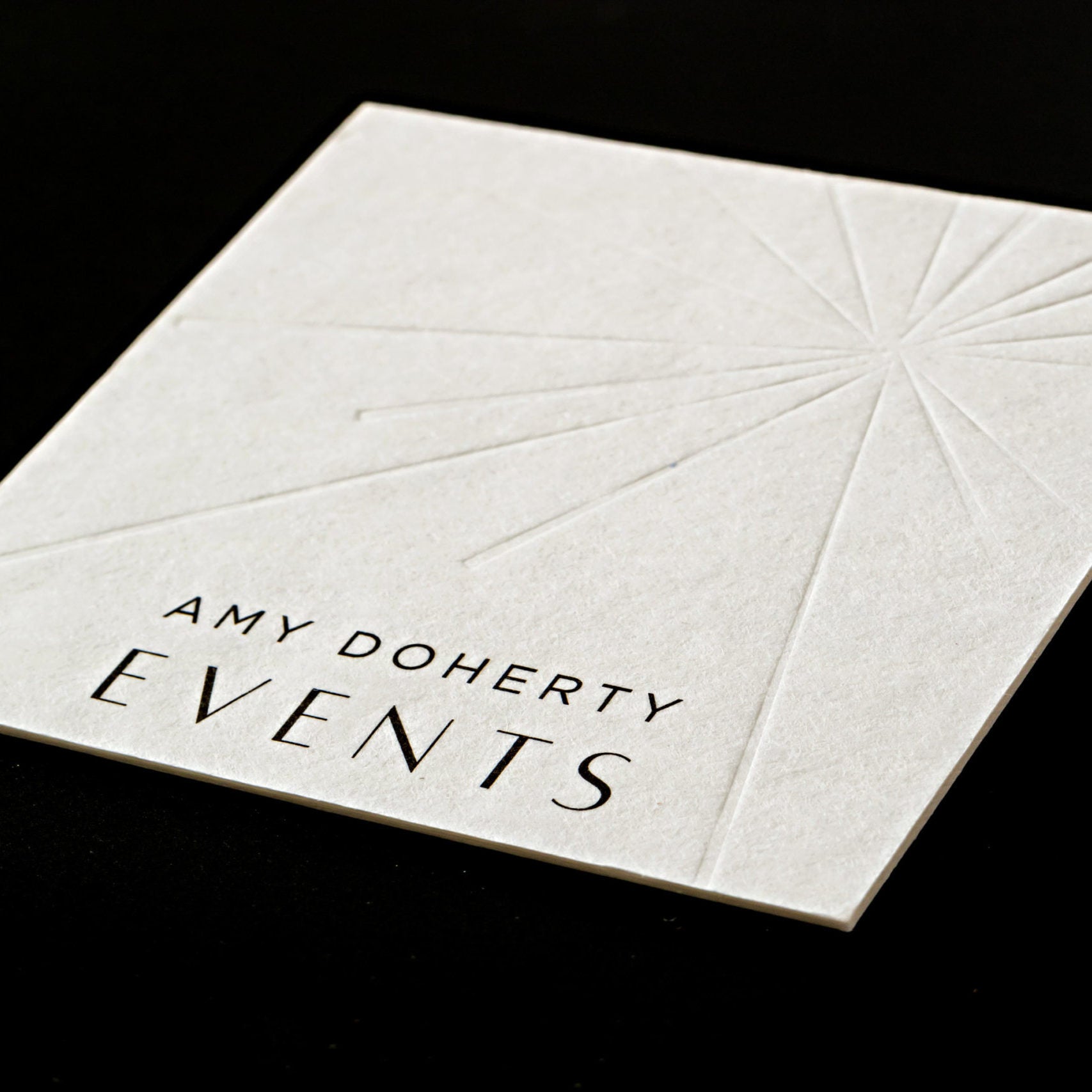

Letterpress / Debossing

Letterpress printing is a type of relief printing where the raised areas of a plate are inked and then pressed against paper, transferring the ink to the paper and creating an deep debossed impression.

-

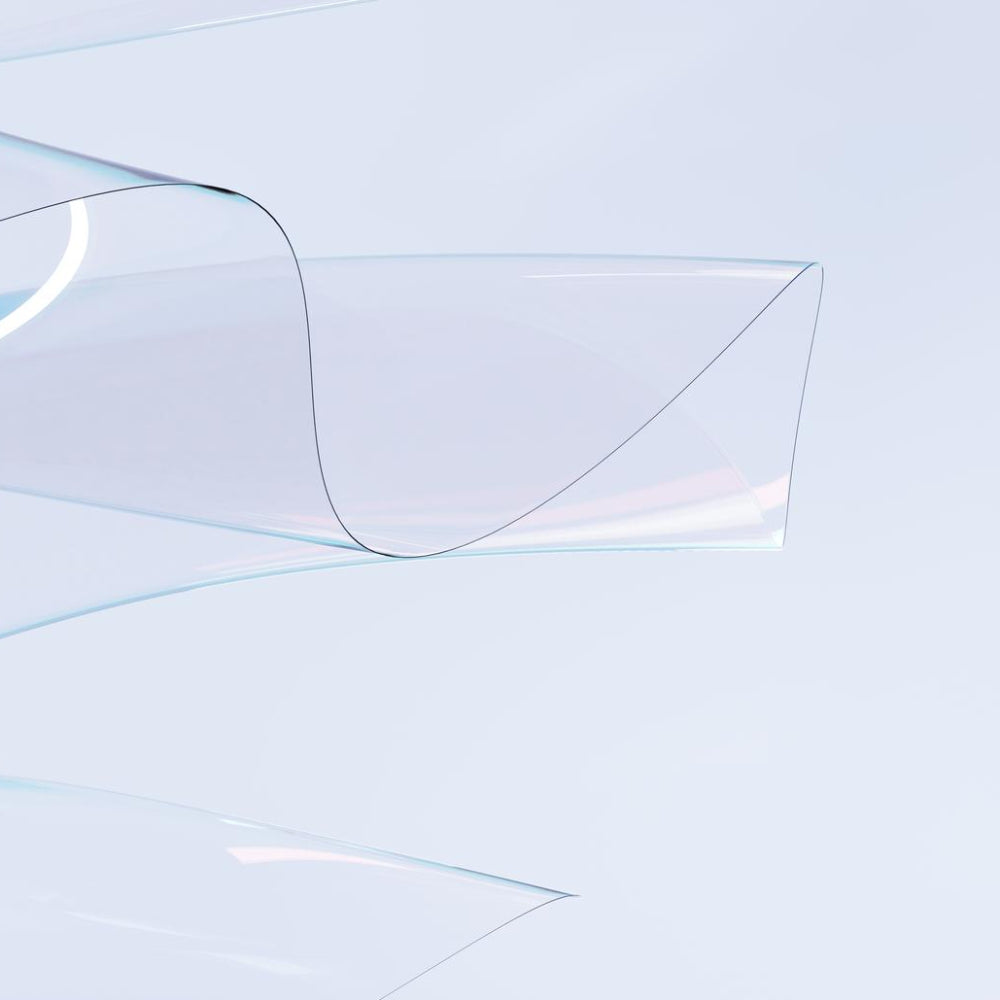

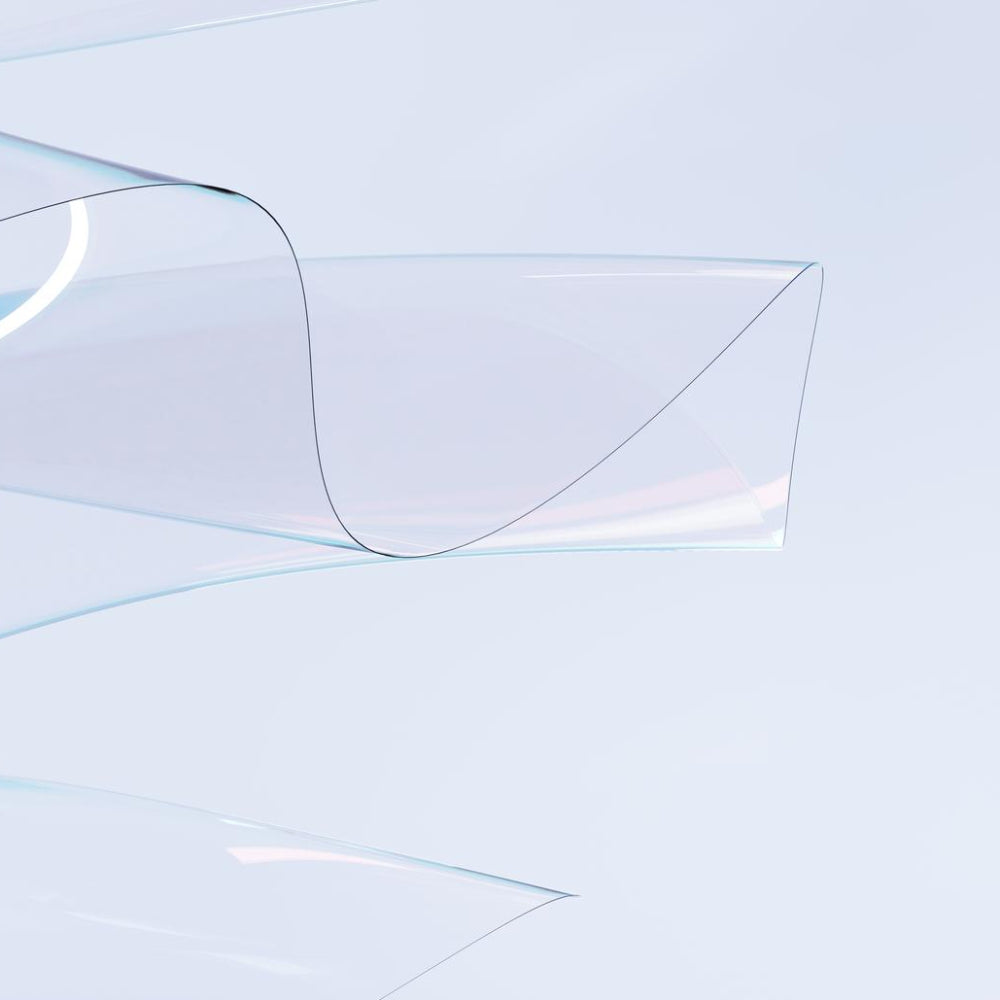

Spot Gloss UV

Spot UV is a varnish applied to certain areas of a printed piece, such as the logo or title, in order to create a shiny, glossy effect. It can be used to make elements of your design really stand out, or to add an extra layer of depth and sophistication.

-

Edge Painting

Edge painting is a printing process in which the edges of a printed product, such as a business card or book cover, are painted with a solid color - usually a Pantone PMS color.

-

Edge Foiling

Edge foiling is a printing process in which a thin strip of foil is applied to the edges of a printed product, such as a business card or book cover, to add a metallic or reflective finish.

-

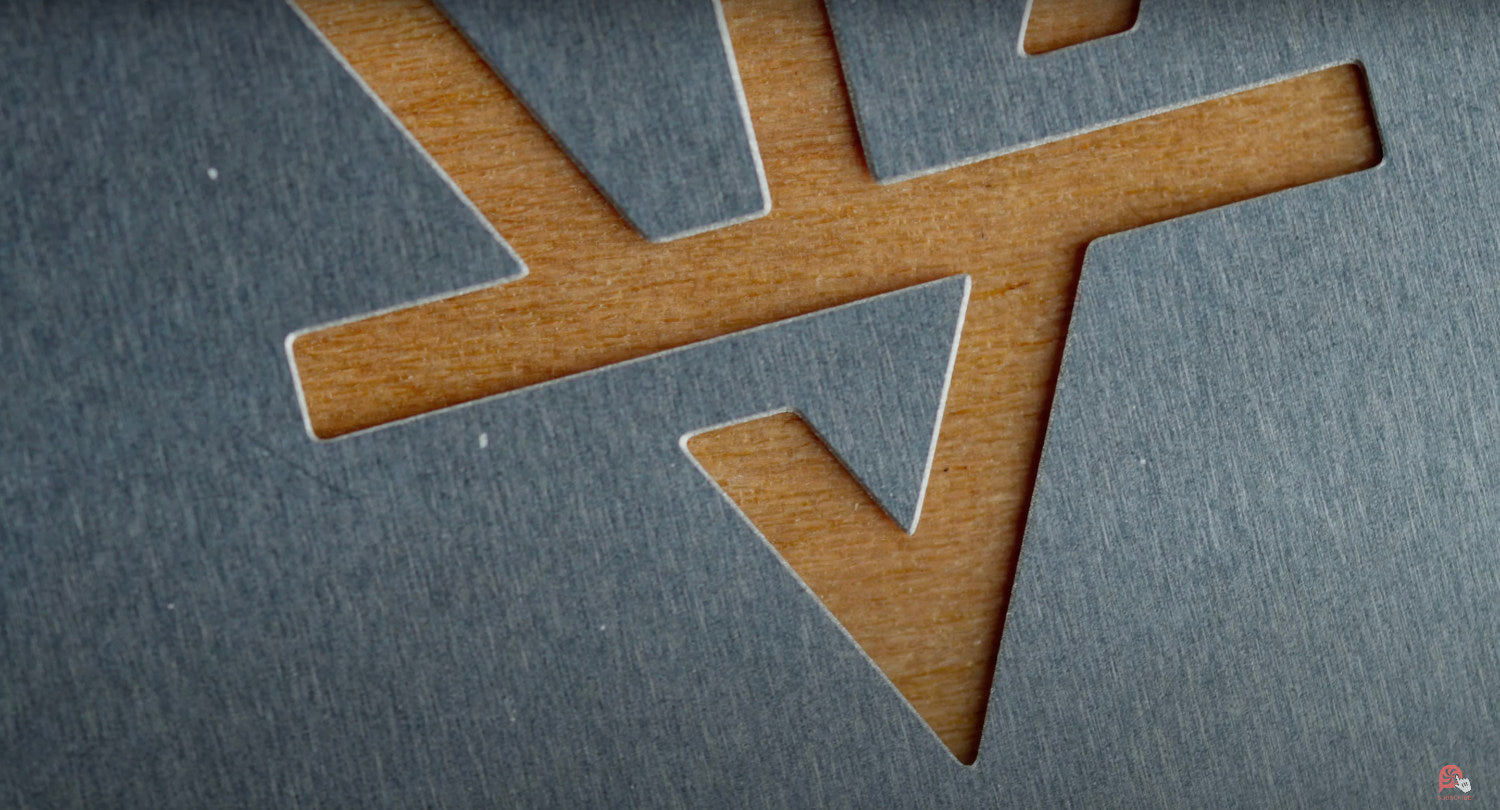

Laser Cutting

Laser cutting is a precise and efficient way to cut materials, such as metal, wood, plastic, or paper. and it can produce intricate shapes and detailed cuts that are difficult or impossible to achieve with other methods.

-

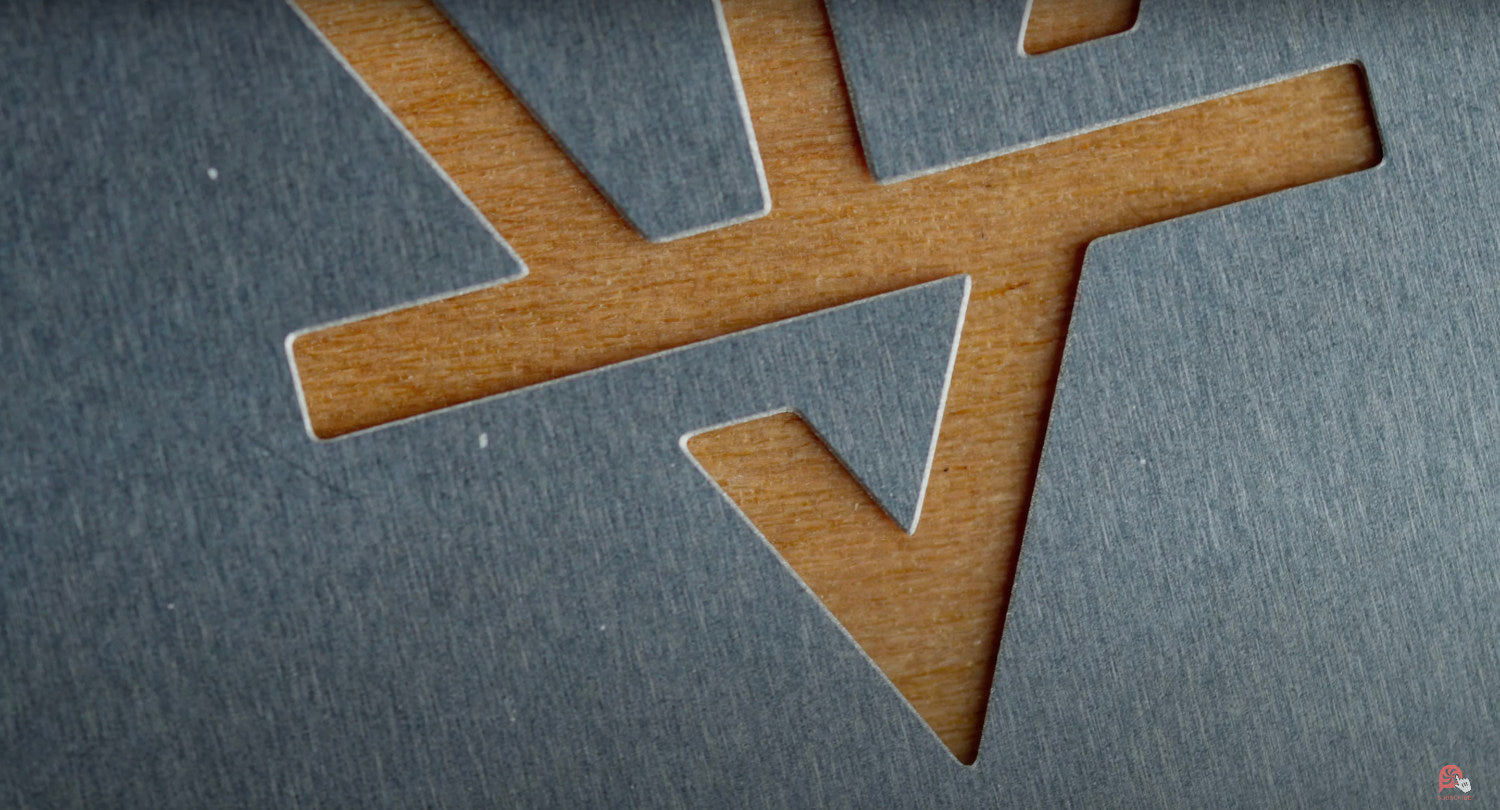

Etching: Laser & Chemical

Laser etching is a sophisticated manufacturing process whereby a laser beam is used to remove material from the surface of an object to create images, text, or patterns.

-

Spot Color Printing

Spot color printing is used to achieve a specific color or hue that cannot be achieved using the standard four-color printing process (CMYK), which uses cyan, magenta, yellow, and black ink to produce a full range of colors.

-

Paper Folding & Scoring

Scoring is the process of creating a crease in the paper by pressing a sharp tool into it, while folding is the process of bending the paper along the scored line.

-

Hole Drilling / Punching

Using a rotating drill bit, holes are drilled into sheets of paper or other materials, such as cardboard or plastic. It is commonly used to create products that require holes for binding or for hanging.

-

Varnishes

Varnishes can be used to seal in printing ink, add gloss or a leveling effect, alter the surface texture, provide a barrier against water and dirt, and protect the paper from fading or yellowing over time.

-

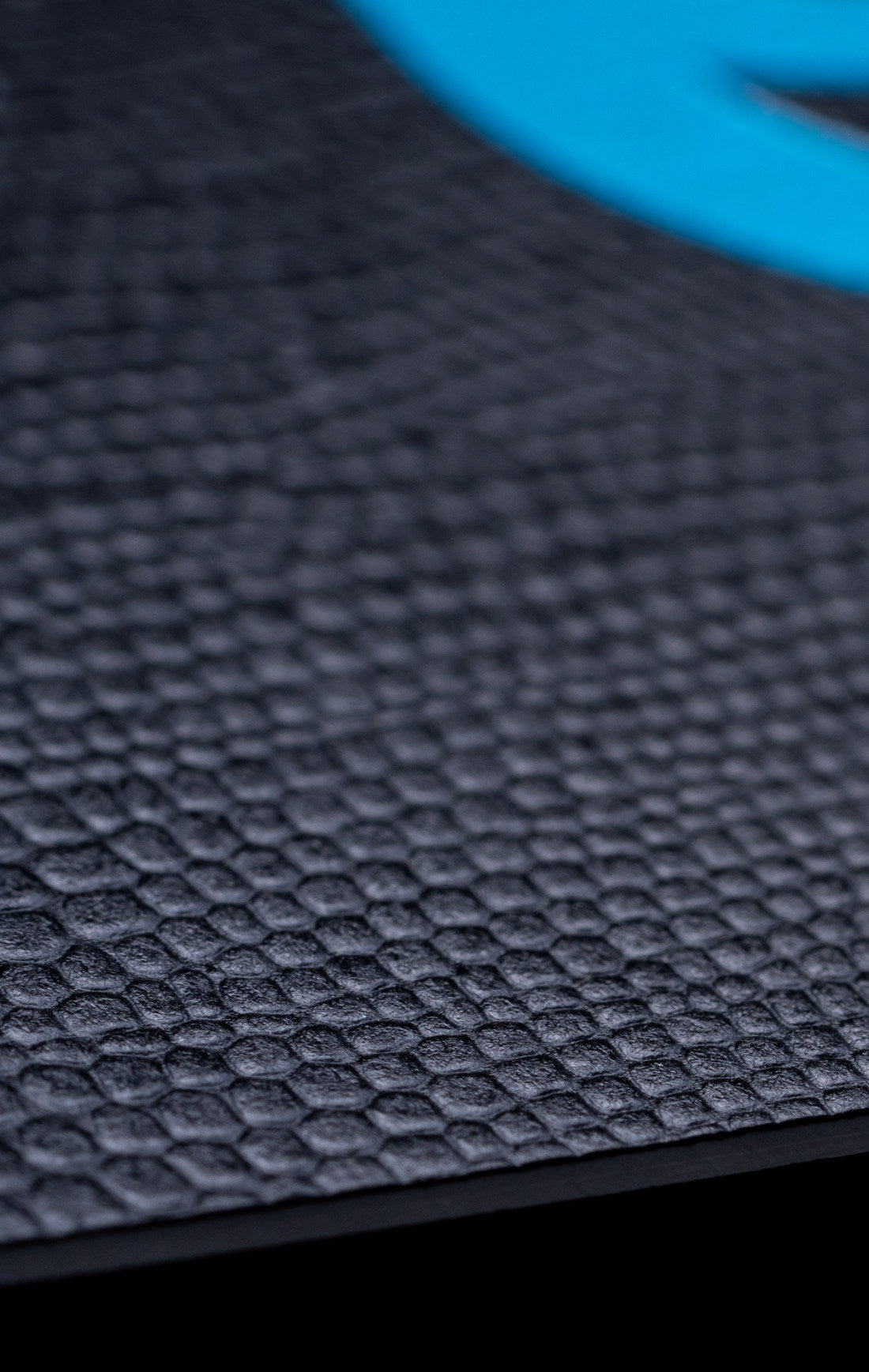

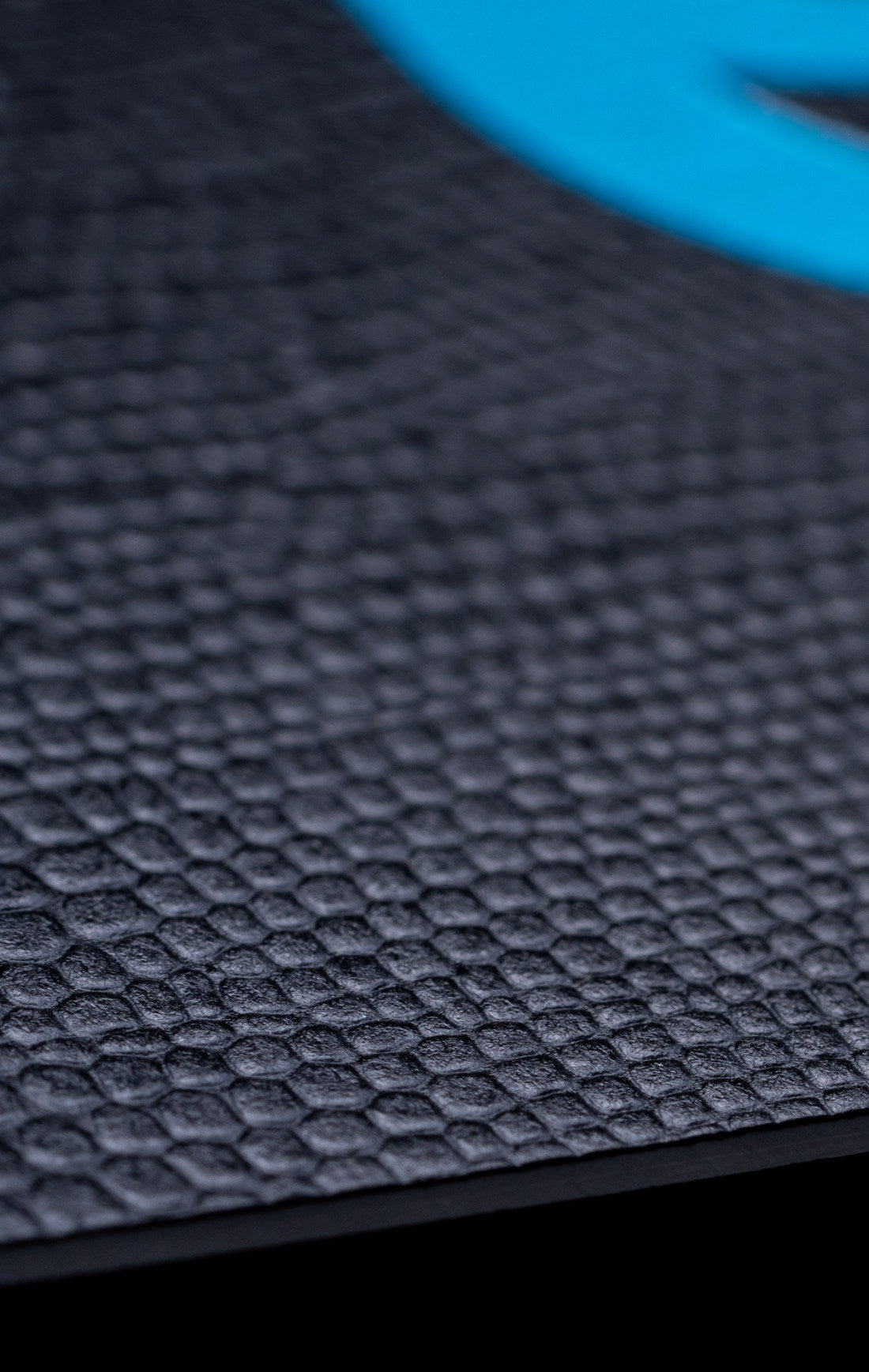

Lamination

Lamination is the technique of bonding together sheets of paper with a layer of plastic film to make them more durable and presentable. It is a common way of protecting documents or making them look more attractive.

-

Duplexing

Paper duplexing is the process of bonding 2 or more sheets together to create a thick and luxury board. We often bond two different types of papers together creating very interesting and exotic results.

Order Samples

Receive by mail tons of real examples of all our special finishes and compare for yourself.